Food

Enzymes are specialized proteins that act as catalysts to speed up a specific reaction. In most cases, enzymes used in food are used as processing aids where they aid in the manufacturing of food or food ingredients, but do not have a function in the final food product.

Enzymes have played an important part in food production for centuries. Today, nearly all commercially prepared foods contain at least one ingredient that has been made with enzymes. Some examples of typical enzyme applications are listed below.

Baking

Enzymes can be used in baked goods to reduce dependence on some traditional, less desirable ingredients while maintaining the desirable characteristics of the baked goods throughout shelf life. This also allows for simplified ingredient lists on the final food label.

Below are examples of enzymes used in baking and the benefits they provide.

Dairy

In the dairy industry, enzymes are required for production of cheeses, yogurt, and other dairy products. Enzymes can also be used in a more specialized fashion to improve texture, flavor, or digestibility in dairy products. Four of the more common types of enzymes and their role in the dairy industry are described below.

Rennet and lipase, two key cheese enzymes, traditionally have been obtained through animal derived origins. Modern biotechnology has provided, consistent, and cost-effective microbial versions that allow cheesemakers to meet the demands of consumption.

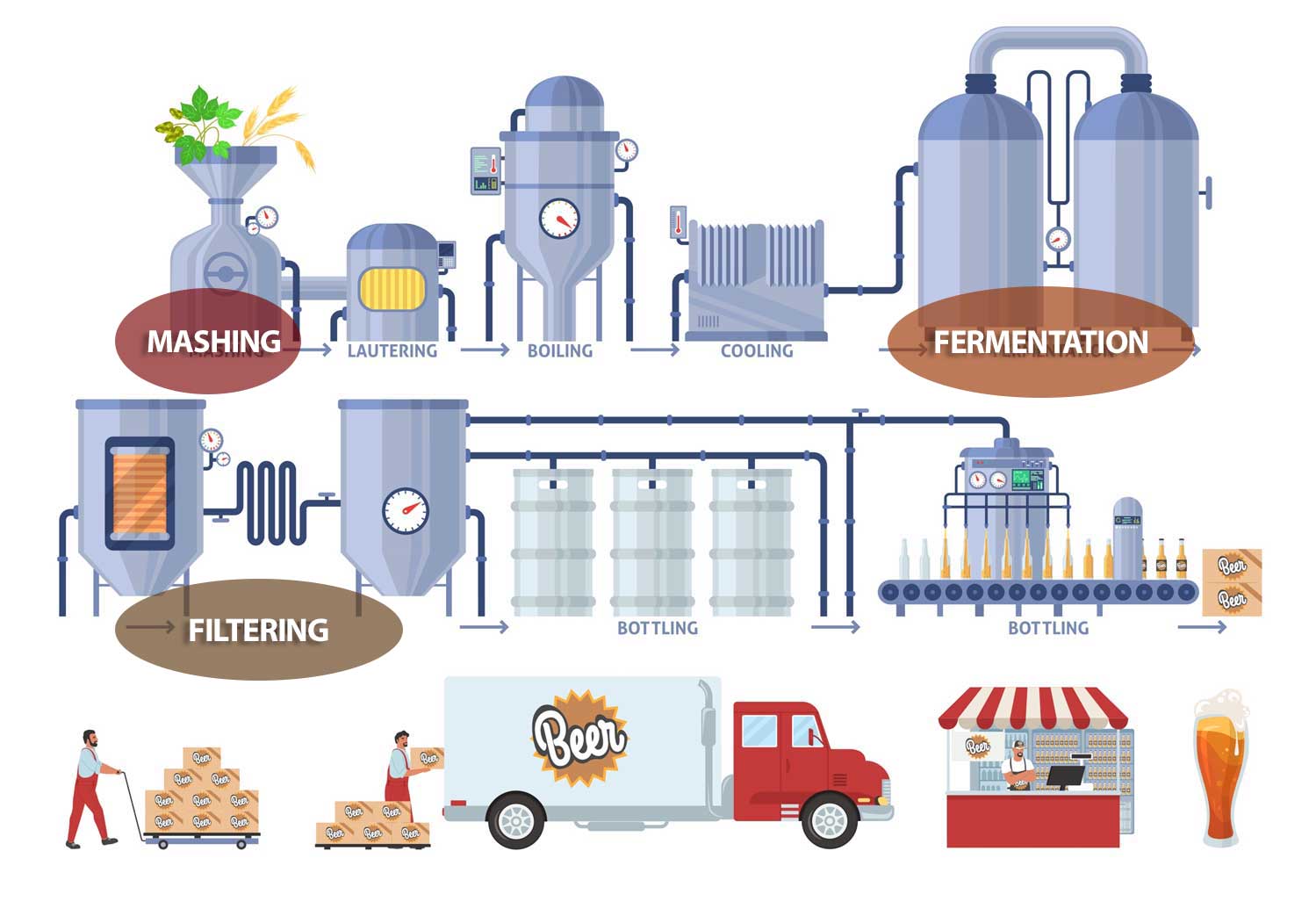

Brewing

Enzymes play a significant role in the brewing industry where they can assist brewers year-round despite fluctuations in raw material quality and prices.

Specialized enzymes can optimize the brewing process which can support decreased energy consumption. Below are some examples of brewing enzymes and where they are used in the brewing process.

Food and Nutrition (“processing”)

Enzymes can be used in various processing applications in the food industry. Below are a few examples of Enzyme applications used in food and nutrition processing.

Grain Processing

Oilseed Processing

Fruit and Vegetable Processing

Protein Processing

Other Applications

For more information about food enzymes and how they are regulated view the documents below or view the links in our links tab:

- Industrial Biotechnology Journal Publication: “The Generally Recognized As Safe (GRAS) Process for Industrial Microbial Enzymes” (PDF)

- ETA responds to recent Food and Chemical Toxicology article,” GRAS from the ground up: Review of the Interim Pilot Program for GRAS notification” by Hanlon et al., 2017 (PDF)

- FDA GRAS Recognized as Safe (PDF)

- Pariza and Johnson paper “Evaluating the Safety of Microbial Enzyme Preparations Used in Food Processing: Update for a New Century”

Food Allergen Information

For information about enzymes and food allergens, read the following document: